Section

From Production to Delivery: Digitize Manufacturing Ops with Dynamics 365 Supply Chain Management

Section

Table of Contents

- Deploying Dynamics 365 Supply Chain Management in Manufacturing

- Improving Production Efficiency and Outcomes with AI and IoT

- Utilizing Real-Time Data for Streamlined Operations

- Advanced Demand Planning and Forecasting

- Optimizing Logistics and Fulfillment

- Agile Supply Chain Management to Adapt to Market Changes

- Building a Sustainable Supply Chain

- Conclusion

Section

This blog explores the integration of Dynamics 365 Supply Chain Management into manufacturing operations, emphasizing its impact on demand planning and forecasting. We delve into how this robust platform digitizes various stages from production to delivery, enabling manufacturers to enhance efficiency, reduce errors, and adapt more quickly to market changes. Through real-world examples and expert insights, we demonstrate how Dynamics 365 helps businesses optimize their supply chains and stay ahead in a competitive landscape.

Section

The manufacturing industry faces relentless challenges from fluctuating market demands to frequent supply chain disruptions. In response, Microsoft Dynamics 365 emerges as a powerful solution to boost agility and resilience. Dynamics 365 Supply Chain Management transforms manufacturing processes, redefining how resources are planned, and products are distributed.

This robust platform merges cutting-edge analytics, artificial intelligence, and real-time data capabilities, empowering manufacturers to master the complexities of supply chain disruptions, shifting market demands, and pressing sustainability objectives. By leveraging cloud computing, AI, and real-time analytics, Dynamics 365 doesn’t just help manufacturers survive; it enables them to flourish. It transforms traditional supply chain operations into agile, robust, and efficient powerhouses.

Section

Deploying Dynamics 365 Supply Chain Management in Manufacturing

Microsoft Dynamics 365 Supply Chain Management has helped the manufacturing industry make the shift to digital transformation by offering an easier to use and affordable option than most other ERP solutions in the market. Its intuitive interface and advanced solutions can be tailored to the unique challenges of this sector to extend its role beyond typical ERP functionalities, embedding insights and controls into every stage of the manufacturing process from inventory management to customer service.

- Integration with Microsoft Technologies: One of Dynamics 365’s key strengths is its seamless integration with other Microsoft technologies such as Azure, Power BI, and Microsoft 365. This integration enables a unified platform where data flows freely between systems, providing a single source of truth and facilitating better decision-making. For instance, Azure IoT capabilities can be leveraged to track production equipment in real-time, while Power BI processes this data to deliver actionable insights directly to decision-makers.

- Streamlining Supply Chain Operations: Dynamics 365 excels in streamlining operations across the supply chain. It offers comprehensive modules for managing procurement, production, inventory, and distribution. These modules are interconnected, allowing for an agile response to changes in demand or supply conditions. The platform’s ability to provide real-time analytics and forecasting also plays a critical role in ensuring that manufacturing processes are lean, efficient, and responsive to market dynamics.

Section

Section

Transform your manufacturing operations with Dynamics 365!

Section

Improving Production Efficiency and Outcomes with AI and IoT

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) within Dynamics 365 Supply Chain Management is transforming manufacturing production lines. These technologies enhance production capabilities and bring substantial improvements in efficiency and reduction in operational downtimes.

- AI-Driven Insights: AI capabilities in Dynamics 365 analyze vast amounts of data to provide insights that were previously inaccessible. For example, AI can predict machine failures before they occur, allowing for preventive maintenance that minimizes unplanned downtime. Additionally, AI-driven optimization of production processes can significantly enhance output quality and speed, ensuring that manufacturers can meet demand without compromising on quality.

- IoT for Real-Time Monitoring: IoT devices integrated with Dynamics 365 enable real-time monitoring of production equipment and environments. This monitoring facilitates a deeper understanding of machine performance and environmental conditions, impacting product quality. Real-time data collected from IoT devices can trigger alerts for immediate action, from adjusting machine parameters to addressing quality deviations, ensuring continuous production without interruptions.

Section

Utilizing Real-Time Data for Streamlined Operations

For manufacturers, the ability to apply real-time data is crucial for maintaining a competitive edge. Dynamics 365 helps manufacturers excel in this area by providing tools that allow manufacturers to access, analyze, and act upon data from across the entire supply chain instantly.

- Operational Responsiveness: With Dynamics 365, manufacturers can monitor every aspect of their operations, from inventory levels to production statuses. This real-time visibility ensures that decision-makers can react swiftly to any changes or disruptions, such as supply shortages or sudden spikes in demand. By enabling a quicker response, Dynamics 365 helps minimize downtime and optimize production schedules, ensuring that customer demands are met efficiently and effectively.

- Enhanced Decision Making: The real-time analytics capabilities of Dynamics 365 empower manufacturers with data-driven insights that drive better decision-making. For example, if real-time data indicates a bottleneck at one stage of production, managers can immediately allocate resources or adjust processes to address the issue. Similarly, real-time sales data can help adjust production levels to prevent overproduction and excessive inventory costs.

Real-World Examples:

- Grundfos: This company utilized Microsoft Power BI to enhance its manufacturing processes. Power BI’s light ETL functionality and user-friendly interface were particularly beneficial, helping Grundfos become more data-driven and improving their operational efficiency.

- Sandvik Coromant: Also leveraging Power BI, Sandvik Coromant found the tool very powerful for top management. The ability to use reports easily helped the company advance in its data-driven initiatives.

- Sight Machine on Azure: This case study involves the use of Azure’s IoT and AI capabilities through Sight Machine, an AI-enabled analytics platform. It enables the normalization and contextualization of plant floor data in real-time. This integration helps manufacturers gain actionable insights, transform operations, and unlock new value by utilizing digital twins.

Section

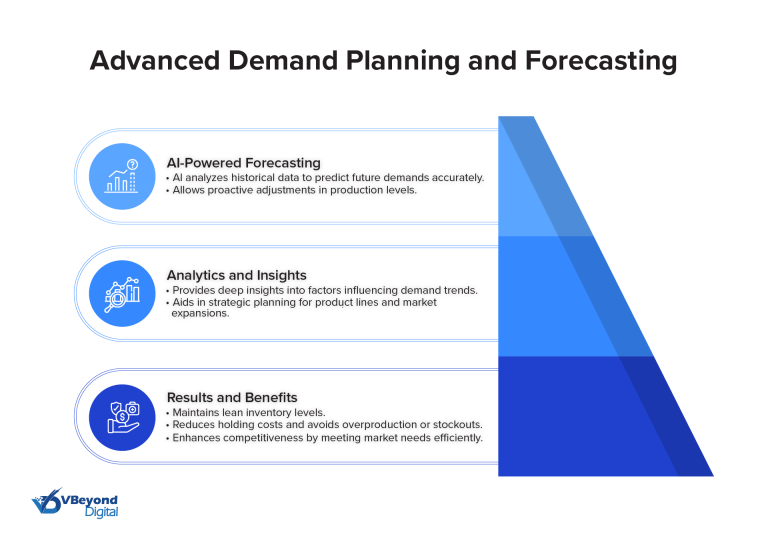

Advanced Demand Planning and Forecasting

Dynamics 365 is instrumental in revolutionizing demand planning and forecasting within the manufacturing industry. Its advanced tools, powered by AI and machine learning, enable manufacturers to predict future demands with greater accuracy, thereby optimizing production schedules and inventory management.

- AI-Powered Forecasting: The AI capabilities in Dynamics 365 analyze historical data and identify patterns that might not be evident to human analysts. This advanced forecasting helps manufacturers anticipate demand fluctuations more accurately, allowing them to adjust production levels proactively. Such precision in forecasting is essential for maintaining lean inventory levels, reducing holding costs, and avoiding stockouts or overproduction.

- Analytics and Insights: Beyond simple forecasting, Dynamics 365 provides deep analytics that help manufacturers understand the factors influencing demand trends. This insight allows for the strategic planning of product lines, promotions, and market expansions. By understanding and anticipating market needs, manufacturers can tailor their strategies to meet consumer demands effectively and gain a competitive advantage.

Section

Optimizing Logistics and Fulfillment

Dynamics 365 significantly enhances logistics and fulfillment strategies, offering manufacturers robust tools to streamline these critical aspects of the supply chain. By automating key processes and optimizing distribution management, Dynamics 365 helps ensure products are delivered efficiently and customer satisfaction is maintained at high levels.

- Automated Order Processing: Dynamics 365 automates the entire order processing cycle, from order receipt to fulfillment. This automation reduces manual errors and speeds up the processing time, allowing companies to handle higher volumes of orders with greater accuracy. Additionally, the system provides updates in real-time, keeping customers informed about the status of their orders, which enhances the overall customer experience.

- Intelligent Route Planning and Distribution Management: Leveraging AI and advanced analytics, Dynamics 365 optimizes delivery routes and schedules to ensure the most efficient use of resources. This not only reduces delivery times but also lowers transportation costs and minimizes environmental impact. For global operations, this optimization is crucial as it ensures timely deliveries across diverse geographic locations, regardless of local challenges.

Section

Agile Supply Chain Management to Adapt to Market Changes

Agility in supply chain management is crucial for manufacturers to adapt quickly to market changes and supply chain disruptions. Dynamics 365 provides robust features that support rapid scaling of operations and seamless integration of new processes or technologies, helping businesses maintain resilience and competitiveness.

- Features for Rapid Adaptation: Dynamics 365 equips manufacturers with tools that facilitate quick adaptation to changing market conditions. These include modular applications that can be customized and scaled as needed, allowing businesses to respond swiftly to new opportunities or challenges. The platform also supports the adoption of new technologies, such as blockchain and advanced robotics, through its flexible and extensible architecture.

- Handling Supply Chain Disruptions: In the face of supply chain disruptions, such as those caused by global crises or local issues, Dynamics 365’s real-time analytics and communication tools help manufacturers maintain operational continuity. By providing an overarching view of the supply chain, Dynamics 365 enables companies to identify potential risks early and devise contingency plans effectively.

Examples of Agile Supply Chain Management:

- Michael Hill: This international jeweller utilized Dynamics 365 to overhaul its retail operations significantly. By adopting Dynamics 365 Commerce and Supply Chain Management, Michael Hill achieved a more integrated approach, allowing for better inventory visibility and more flexible customer service options. This system overhaul was particularly crucial during the COVID-19 pandemic, enabling the company to adapt quickly to new consumer behaviors and logistical challenges (Source: The Microsoft Cloud Blog).

- Chemist Warehouse: As a leading retailer in Australia, Chemist Warehouse moved its operations to Dynamics 365 to support its international expansion and enhance customer experiences. The transition involved implementing Dynamics 365 Finance, Supply Chain Management, and Commerce, which helped streamline operations and offer a more integrated customer experience across their physical and online stores (Source: The Microsoft Cloud Blog).

Section

Building a Sustainable Supply Chain

Even though the manufacturing industry is looking to shift to more sustainable supply chain and logistics activities, it is more than a compliance measure – it’s important from the purview of the brand and building trust in the market and among customers. Dynamics 365 supports manufacturers in implementing sustainable practices across their operations, from reducing waste to managing reverse logistics efficiently.

- Support for Circular Economies: Dynamics 365 facilitates the adoption of circular economy practices, such as recycling and the reuse of materials. The platform’s tracking and analytics capabilities ensure that materials can be traced through their lifecycle, helping companies to maximize resource utilization and minimize waste.

- Efficient Resource Management: By optimizing production processes and supply chain operations, Dynamics 365 helps manufacturers reduce energy usage and waste production. This not only contributes to environmental sustainability but also leads to cost savings, creating a win-win scenario for businesses and the environment alike.

- Role in Reverse Logistics: Dynamics 365 also plays a crucial role in managing reverse logistics processes, which are essential for recycling and refurbishing used products. Efficient management of these processes not only supports sustainability but also opens up new revenue streams by transforming waste into valuable resources.

Case Study: The GWA Group faced multiple challenges during the pandemic, such as shifting customer demands and supply chain disruptions. To address these issues, they chose to accelerate their digital transformation rather than scale back, implementing Dynamics 365 to manage their entire business ecosystem, which includes Customer Care, Warehouse Management, Finance & Operations, Supply Chain, Commerce, and Marketing. This strategic move not only streamlined their operations by reducing complexity but also introduced greater flexibility and agility as industry dynamics changed. The implementation has transformed their business operations and the way they think about business processes.

For further details, you can read more about GWA Group’s experience on Microsoft’s Dynamics 365 Blog: GWA Group Case Study.

Section

Conclusion

Dynamics 365 offers a comprehensive solution that addresses the diverse needs of different types of manufacturing operations at scale. For industry leaders and decision-makers, investing in Dynamics 365 is not just about upgrading technology—it’s about transforming their entire operational framework to be more responsive, efficient, and forward-thinking. As we move towards a future marked by further digital innovation, Dynamics 365 stands ready to lead the way in transforming supply chains from production to delivery, ensuring manufacturers not only meet the current demands but set new benchmarks in manufacturing excellence.