Section

Real-Time Supply Chain Analysis in Manufacturing Data Integration with Power BI

Section

Table of Contents

- The Strategic Importance of Real-Time Data in Modern Manufacturing Data Integration

- Deep Dive into Power BI’s Technical Capabilities for Manufacturing Data Integration

- Enhancing Visibility Across the Supply Chain

- Real-World Applications: Power BI in Action

- Exploring Power BI’s Core Features for Supply Chain Optimization

- Implementing Power BI: A Blueprint for Manufacturing Data Integration CIOs

- Measuring the Impact: Benefits of Real-Time Supply Chain Analytics

- Future Directions in Manufacturing Data Integration Analytics

- Conclusion

Section

In today’s manufacturing sector, effective decision-making relies heavily on data-driven insights. This blog delves into how Power BI facilitates real-time supply chain analysis, enabling manufacturers to monitor operations closely and make decisions swiftly. By integrating diverse data sources and providing accessible visual analytics, Power BI helps businesses maintain competitive advantages through improved visibility and responsiveness in their supply chain processes. This tool’s capabilities are crucial for addressing the dynamic demands of manufacturing logistics and production scheduling.

The manufacturing data integration industry faces growing pressure to deliver faster, more efficiently, and with greater adaptability. Supply chains are now more complex, with global suppliers, fluctuating demands, and unexpected disruptions becoming the norm. Many companies struggle to keep pace with this dynamic environment, where even the smallest delays can ripple through production, causing costly bottlenecks and inefficiencies.

This is where real-time data becomes a game-changer. Manufacturers can no longer afford to rely on outdated reports or manual data entries. They need immediate, accurate insights to stay competitive and responsive to changes. Real-time supply chain analysis, powered by tools like Power BI, allows businesses to not just track, but actively manage their operations as they happen. Companies that harness these insights are seeing dramatic improvements, from slashing onboarding times to boosting production efficiency and avoiding costly downtime.

By diving into Power BI’s capabilities, manufacturers can shift from a reactive to a proactive approach, optimizing everything from resource allocation to bottleneck resolution—all in real time.

The Strategic Importance of Real-Time Data in Modern Manufacturing Data Integration

Manufacturing data integration competitiveness increasingly hinges on the ability to integrate real-time data into operational strategies, production methods, and QC. This integration enables manufacturers to swiftly adapt to market changes and supply chain disruptions, maintaining operational continuity and reducing downtime. Real-time data fosters a proactive rather than reactive management style, crucial for maintaining competitive advantage in a global market.

Immediate data utilization through Power BI can significantly enhance decision-making and operational agility. By leveraging real-time insights, manufacturers can quickly identify and address inefficiencies, forecast demands more accurately, and improve overall supply chain responsiveness. This capability is crucial for manufacturers facing highly variable demand and supply conditions.

Deep Dive into Power BI’s Technical Capabilities for Manufacturing Data Integration

Power BI’s architecture is uniquely positioned to facilitate manufacturing data integration across various systems and platforms. It serves as a bridge connecting disparate data sources, including IoT devices and ERP systems, into a coherent, real-time analytical tool. By centralizing data, Power BI allows manufacturers to gain a comprehensive overview of their operations, enhancing the ability to make informed decisions quickly.

- Data Collection and Integration: Power BI can integrate data from multiple sources, including production line sensors, ERP systems, and customer feedback channels. This integration supports a unified view of operations and supply chain management.

- Real-Time Processing: The ability to process and analyze data in real time is a cornerstone of Power BI. This capability allows manufacturers to monitor operational metrics and respond to anomalies as they occur, minimizing potential disruptions.

Key Features Unpacked

Power BI offers several features crucial for manufacturing data integration and improving operational efficiency. These features support operational strategies for managing supply chain disruptions and enhance overall operational agility.

- Dashboard Customization: Manufacturers can customize dashboards to display key metrics relevant to different aspects of the supply chain, from procurement to product delivery. This customization allows for targeted insights that are actionable and relevant.

- Advanced Analytics: With built-in machine learning capabilities, Power BI can forecast trends, perform root cause analysis, and optimize processes. This analytical power supports strategic decisions that align with company goals and market demands.

- Alerts and Notifications: Automated alerts help keep all stakeholders informed about critical metrics and system outputs, ensuring that deviations from the norm are addressed promptly.

Enhancing Visibility Across the Supply Chain

From Raw Materials to Finished Goods

Power BI enhances the visibility of the entire manufacturing data integration process, from the acquisition of raw materials to the delivery of finished goods. By integrating Manufacturing data integration, Power BI provides manufacturers with a transparent view of their inventory levels, production rates, and potential bottlenecks.

- Real-time Inventory Management: Power BI enables real-time tracking of inventory levels across multiple locations, reducing the risk of overstocking or stockouts and improving operational efficiency.

- Production Monitoring: Real-time data visualization of production lines helps identify inefficiencies and delays, allowing for prompt adjustments to maintain workflow continuity.

Identifying and Resolving Disruptions

Operational strategies for managing supply chain disruptions are crucial, and Power BI supports these strategies by providing tools to identify and mitigate risks before they escalate.

- Disruption Alerts: Power BI can set up custom alerts to notify managers about potential disruptions based on predefined criteria, such as delays in raw material delivery or a sudden drop in production output.

- Bottleneck Analysis: Analytical tools within Power BI identify bottlenecks in the supply chain, allowing for quick resolution and adjustments to maintain optimal production flow.

Real-World Applications: Power BI in Action

Case Study 1: Sertecpet

Problem: Sertecpet, operating in the complex and dynamic oil industry, faced significant challenges in optimizing its operational efficiency across geographically dispersed sites. The lack of real-time data and advanced analytics hindered effective decision-making and operational management.

Solution: The company implemented Power BI to leverage its powerful data visualization and analytics capabilities. This allowed for the integration of real-time data from various operations, which was crucial for monitoring and optimizing processes across all locations.

Benefit: The adoption of Power BI enabled Sertecpet to significantly enhance its operational efficiency and decision-making processes. The real-time insights gained through the platform led to optimized resource allocation, better production scheduling, and ultimately, cost reductions. These improvements have been crucial in maintaining competitive advantage in the volatile energy market.

Source: Sertecpet and Power BI

Case Study 2: Zeiss Group

Problem: Zeiss Group struggled with handling the vast amounts of data generated from its discrete manufacturing processes, which impeded the company’s ability to perform in-depth data analysis and real-time operational adjustments.

Solution: By integrating Azure Synapse Analytics with Power BI, Zeiss established a more robust data analytics framework that enhanced data processing and integration capabilities. This setup provided a unified platform for real-time data analysis and decision-making.

Benefit: The solution empowered Zeiss Group to achieve deeper insights into its manufacturing data integration operations, leading to improved production planning and quality control. Enhanced data integration and analytics capabilities facilitated more informed and timely decisions, driving operational efficiencies and supporting proactive management of manufacturing complexities.

Source: Zeiss Group’s Data Strategy

Case Study 3: Eberspächer

Problem: Eberspächer needed to enhance its data management capabilities to handle the intricate and extensive data from its global manufacturing operations more effectively.

Solution: The implementation of Excel and discreet manufacturing data integration tools was aimed at refining the company’s data processing and integration, ensuring accurate and efficient data handling across multiple locations.

Benefit: This strategic approach led to significant improvements in operational efficiency, with better capacity to forecast, manage quality control, and plan production. The enhanced data management capabilities resulted in cost savings and optimized operational workflows, which were critical in boosting overall productivity and maintaining high standards in manufacturing.

Source: Eberspächer’s Manufacturing Innovations

Exploring Power BI’s Core Features for Supply Chain Optimization

Interactive Dashboards and Real-Time Alerts

Power BI significantly enhances Manufacturing data integration supply chain management by providing interactive dashboards that offer real-time insights and visualizations. These dashboards are customizable, allowing manufacturers to focus on key metrics that reflect the health and efficiency of their supply chains. For instance, users can monitor everything from inventory levels and production rates to delivery times and return rates, enabling them to make informed decisions swiftly.

- Real-Time Alerts: Power BI facilitates the setup of automated alerts that notify users of critical changes or potential disruptions within the supply chain, such as unexpected drops in inventory or delays in shipment times. This feature ensures that potential issues can be addressed before they escalate, thus maintaining smooth operations and reducing downtime.

- Dashboard Sharing and Collaboration: Dashboards can be shared across organizational departments or with external partners, ensuring all relevant stakeholders have access to up-to-date information, fostering a collaborative environment for quick decision-making.

Advanced Analytics and Machine Learning

Power BI integrates advanced analytics and machine learning to provide deeper insights into supply chain operations, enhancing manufacturing data integration and supporting the development of operational strategies for managing supply chain disruptions.

- Predictive Analytics for Maintenance and Demand Forecasting: Using historical data, Power BI helps predict future trends in equipment maintenance and product demand. This predictive capability allows for better scheduling of maintenance to avoid unexpected breakdowns and ensures adequate stock levels are maintained to meet consumer demand without overstocking, thereby improving operational efficiency.

- Machine Learning for Enhanced Decision Making: Power BI’s machine learning models analyze data patterns to help forecast future outcomes. This enables manufacturers to anticipate and mitigate risks, optimize production processes, and effectively manage resources.

Supply Chain Performance Metrics

By leveraging Power BI, manufacturers can track detailed key performance metrics (KPIs) to gauge the effectiveness of their supply chain operations. Metrics such as order accuracy, production throughput, and supplier performance are visualized in real-time, providing actionable insights that drive continuous improvement.

- KPI Monitoring and Benchmarking: Power BI allows for real-time tracking of KPIs and benchmarking against industry standards or historical performance. This transparency helps identify areas of improvement, set realistic targets, and measure progress towards these goals effectively.

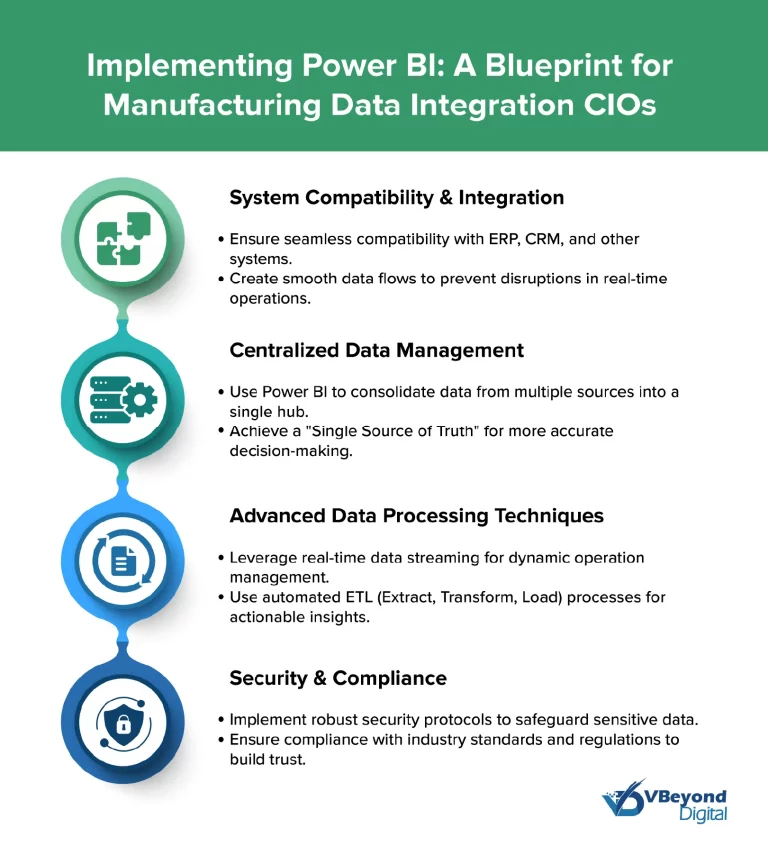

Implementing Power BI: A Blueprint for Manufacturing Data Integration CIOs

Integration Strategies

Integrating Power BI effectively into manufacturing data integration operations involves a sophisticated strategy focusing on advanced technological integration and practical deployment steps. Here’s a detailed breakdown of the essential strategies:

- System Compatibility and Integration: Ensure Power BI compatibility with existing ERP, CRM, and other operational systems to streamline data flows and minimize disruptions during data integration. This ensures a seamless data ecosystem, crucial for real-time manufacturing data integration.

- Centralized Data Management: Utilize Power BI to consolidate data from disparate sources into a centralized hub. This aids in achieving a single source of truth, which is essential for accurate real-time analytics and decision-making.

- Advanced Data Processing Techniques: Employ modern data processing methods such as real-time data streaming and automated ETL (Extract, Transform, Load) processes. These techniques ensure that data is always current and actionable, enhancing the ability to manage operations dynamically.

- Security and Compliance: Implement robust security protocols and compliance checks within Power BI to protect sensitive data and ensure that data handling complies with industry standards and regulations.

User Adoption and Training

Maximizing the value of Power BI across manufacturing data integration operations requires not just technical integration but also organizational adoption:

- Tailored Training Programs: Develop and execute comprehensive training sessions tailored to different user roles within the organization. This will help users understand and leverage Power BI’s capabilities effectively.

- Continuous Support and Iteration: Establish a support framework that provides ongoing assistance and updates on new features and best practices. Regular feedback loops should be created to gather user input and continuously refine the tools and dashboards based on operational needs.

- Creating a Data-Driven Culture: Encourage a culture that relies on data-driven insights by showcasing successful use cases and promoting internal champions who advocate for the benefits of Power BI integration.

Measuring the Impact: Benefits of Real-Time Supply Chain Analytics

Improving Operational Efficiency Benchmarks through Advanced OEE (Overall Equipment Effectiveness) Metrics

The adoption of real-time analytics in manufacturing, specifically through Overall Equipment Effectiveness (OEE), significantly boosts operational efficiency. OEE serves as a comprehensive metric that combines availability, performance, and quality rates to provide a singular view of manufacturing efficiency. By effectively measuring these components, manufacturers can pinpoint areas of loss, improve production capacity, and enhance the utilization of plant assets. The real-time aspect ensures that any deviations are quickly managed, leading to reduced changeover times and enhanced supply chain predictability.

- Availability Monitoring: Real-time tracking of production time against the scheduled benchmarks highlights discrepancies caused by equipment downtime or setup delays, allowing for quick resolution.

- Performance Optimization: Monitoring the actual output against expected performance helps in identifying slowdowns and enabling prompt corrective measures to maintain the desired productivity levels.

- Quality Assurance: Real-time data aids in immediate quality checks, ensuring that only products meeting the standards proceed further in the supply chain.

Leveraging Data for Predictive Maintenance and Resource Optimization

Real-time analytics extend beyond monitoring to predictive capabilities, where data is used to forecast potential equipment failures before they occur. This proactive approach not only minimizes unplanned downtime but also optimizes maintenance schedules, reducing overall operational costs. Moreover, dynamic adjustments in resource allocation based on real-time data ensure optimal use of materials and human resources, thereby enhancing manufacturing data integration efficiency.

- Predictive Maintenance: By analyzing sensor data, systems can predict equipment failures, schedule maintenance, and prevent costly disruptions.

- Resource Allocation: Real-time data allows for the dynamic adjustment of material flows and workforce deployment, maximizing resource utilization and operational efficiency.

Driving Decisions with Real-Time Insights

Real-time analytics empower manufacturers with immediate insights into their operations, facilitating swift decision-making that aligns with current conditions. This capability is crucial for maintaining a competitive edge in a rapidly changing market environment. The integration of real-time data across various platforms and departments ensures a unified operational view, enhancing collaboration and efficiency.

- Immediate Decision-Making: With up-to-the-minute data, manufacturers can quickly respond to changes in production conditions or market demands.

- Enhanced Collaboration: Real-time sharing of insights ensures that all stakeholders are on the same page, fostering a cohesive approach to manufacturing challenges.

Future Directions in Manufacturing Data Integration Analytics

The future of manufacturing analytics is being shaped by several emerging trends that integrate with Power BI to push the boundaries of what is possible in supply chain management:

- IoT and Edge Computing: Increasing use of IoT devices and edge computing will provide even more granular data, enabling manufacturers to monitor operations in real time at every point in the supply chain.

- Advanced Machine Learning Models: The development of more sophisticated machine learning models within Power BI will forecast trends and behaviors with greater accuracy, allowing manufacturers to anticipate and prepare for potential disruptions.

Integrating IoT and AI

The potential for further integration of IoT devices and AI technologies within Power BI offers exciting prospects for deepening insights into manufacturing processes:

- Enhanced Data Collection: IoT devices provide a continuous stream of data that Power BI can analyze, offering insights that were previously unattainable.

- AI-Driven Predictive Analytics: AI technologies can predict outcomes based on real-time data, enabling proactive management of the supply chain and reducing response times to unforeseen disruptions.

Conclusion

The transformative impact of an integrated business intelligence solution like Power BI on manufacturing supply chains cannot be overstated. By enabling real-time data integration, enhancing visibility across the entire supply chain, and empowering manufacturers with actionable insights, Power BI has become an essential tool in modern manufacturing. As technology continues to advance, the strategic value of real-time data analytics will only grow, providing senior executives with the tools they need to make informed decisions, optimize operations, and navigate the complexities of today’s global market.

If you want to explore the capabilities of Power BI and to consider how it can be integrated into your manufacturing operations, our experts can offer a free consultation.