Section

Improving Equipment Performance in Heavy Manufacturing with Power BI: From Data Engineering to Visualization

Section

Table of Contents

- The Significance of Dashboard Analytics in Manufacturing Data Integration

- Diverse Manufacturing Data Integration into Power BI

- The Role of Data Engineering in Manufacturing Data Integration

- Top 10 Types of Power BI Dashboards for Heavy Manufacturing

- Integrating Power BI Dashboards into Business Strategy

- Success Stories in Heavy Manufacturing

- Conclusion

Section

In the blog titled “Improving Equipment Performance in Heavy Manufacturing with Power BI: From Data Engineering to Visualization,” we explore the transformative impact of Power BI on heavy manufacturing sectors. By focusing on manufacturing data integration, the blog outlines the step-by-step process of integrating diverse data sources, engineering robust data pipelines, and developing insightful visualizations. Readers will learn how Power BI enables manufacturers to gain unprecedented clarity on equipment performance, streamline production processes, and make informed decisions that lead to enhanced operational efficiency and productivity. The blog provides practical examples and expert insights, making complex data engineering concepts accessible and actionable for industry professionals.

In heavy machinery manufacturing, the quality of each piece manufactured is pivotal. As manufacturers and suppliers strive for efficiency, leveraging advanced analytics and real-time production monitoring becomes essential. Power BI emerges as a transformative tool, enhancing equipment efficiency through comprehensive data integration and insightful analytics.

The Significance of Dashboard Analytics in Manufacturing Data Integration

Data-Driven Decision Making: In a competitive manufacturing environment, decisions must be based on solid data. Power BI offers a suite of analytics tools that transform raw data into actionable insights, enabling manufacturers to anticipate needs and adjust processes swiftly and accurately.

Seamless System Integration: Power BI seamlessly integrates with existing manufacturing execution system (MES), ERP (enterprise resource planning), CRM (customer relationship management) and IoT devices, pulling diverse data streams into a centralized platform. This integration is crucial for manufacturing data integration, providing a holistic view of operations and empowering stakeholders with the information needed to optimize performance.

Key Benefits:

Enhanced Operational Visibility: Real-time production monitoring allows for immediate response to production anomalies.

Strategic Resource Allocation: Insights from integrated data facilitate smarter decision-making regarding resource allocation, potentially lowering operational costs and enhancing output quality.

Diverse Manufacturing Data Integration into Power BI

Managing and Orchestrating Manufacturing Data

Overview of Data Types:

- IoT and Machine Sensors: Real-time production monitoring from equipment sensors provides crucial insights into machine performance and operational status, enabling proactive adjustments and maintenance.

- ERP and CRM Systems: These platforms are integral for tracking customer interactions, inventory management, and financial operations, ensuring that all levels of manufacturing data integration are aligned and actionable.

- Manual Input Logs: Despite the high level of automation in manufacturing operation, manual logs such as maintenance records are vital for filling in the gaps, offering detailed insights when automated systems fall short.

Challenges in Data Collection:

- Data Silos: The isolated storage of data in disparate systems impedes unified analysis, often causing delays and inconsistencies in decision-making.

- Inconsistent Data Formats: The lack of uniform data formats across systems complicates the integration process, requiring sophisticated transformation tools to standardize data for analysis.

- High Data Velocity: The fast pace at which data is generated from various sources demands robust data management strategies to ensure timely and accurate data processing.

Building Robust Data Pipelines for Power BI:

- Data Extraction Techniques: Utilizing custom connectors and APIs, Power BI efficiently pulls data from diverse sources, ensuring comprehensive data capture.

- Data Transformation: This process involves standardizing and cleansing data, making it suitable for in-depth analysis and reporting.

- Data Loading: Once processed, data is integrated into Power BI, ready for real-time analytics and decision-making.

Data Engineering for Streamlined Analysis:

Automation in Dataflows: Power BI minimizes manual coding and accelerates data integration through automated dataflows, essential for efficient predictive maintenance in manufacturing and real-time production monitoring.

Advanced Integration Features:

Dataflows: These facilitate pre-packaged data services that collect, transform, and load data into Power BI, streamlining the data integration process.

Gateways: They ensure secure data transfer from on-premises systems to Power BI, crucial for handling sensitive manufacturing data integration.

Section

Section

Enhance Manufacturing with Real Insights

The Role of Data Engineering in Manufacturing Data Integration

Building Comprehensive Data Pipelines:

How it Works: Data engineering involves creating pipelines that connect MES, ERP, supply chain, and logistics systems to Power BI. These pipelines extract raw data, transform it into a standardized format, and load it into a unified platform.

Benefits: This process ensures that data from all parts of the manufacturing process is accessible in one place, making it easier to analyze and draw insights. It also reduces the time and effort required to manually gather and consolidate data.

Enabling Precise Forecasting and Predictive Insights:

How it Works: Data engineers develop algorithms that use historical and real-time data to predict future events, such as equipment maintenance needs or production output. These algorithms are integrated into Power BI dashboards for easy access.

Benefits: Manufacturers can anticipate issues before they arise, reducing downtime and improving production efficiency. Predictive insights help in planning and resource allocation, ensuring optimal performance and cost savings.

Integrating IoT Device and Sensor Data:

How it Works: IoT devices and sensors embedded in machinery continuously collect data on parameters like temperature, vibration, and operational status. Data engineers create pipelines to integrate this sensor data into Power BI for real-time monitoring.

Benefits: Real-time visibility into machine performance allows for immediate adjustments and proactive maintenance. This leads to fewer unexpected breakdowns and longer equipment life, enhancing overall operational efficiency.

Optimizing Equipment Performance and Manufacturing Output:

How it Works: By analyzing data from IoT sensors, MES, and ERP systems in Power BI, manufacturers can identify patterns and trends that impact equipment performance. Data engineering ensures that this data is processed and presented in an actionable format.

Benefits: Insights derived from this integrated data help in fine-tuning equipment settings, scheduling maintenance, and improving operational workflows. This leads to higher production quality and better utilization of resources, maximizing output.

Streamlining Data Processing for Real-Time Analytics:

How it Works: Data engineering helps automate the extraction, transformation, and loading (ETL) processes to ensure that data is continuously updated in Power BI. This includes integrating real-time IoT sensor data for up-to-the-minute insights.

Benefits: Real-time analytics enable manufacturers to respond quickly to changes in production conditions, minimizing delays and optimizing processes on the fly. The ability to make data-driven decisions in real-time improves overall operational agility.

Creating a Unified Data Platform:

How it Works: Data engineers consolidate data from multiple systems, including IoT devices, into a single platform using Power BI. This platform provides a 360-degree view of all manufacturing operations.

Benefits: A unified data platform breaks down silos, enabling better collaboration and more informed decision-making across the organization. It supports strategic planning by providing a comprehensive view of all aspects of manufacturing, from supply chain to production to equipment performance.

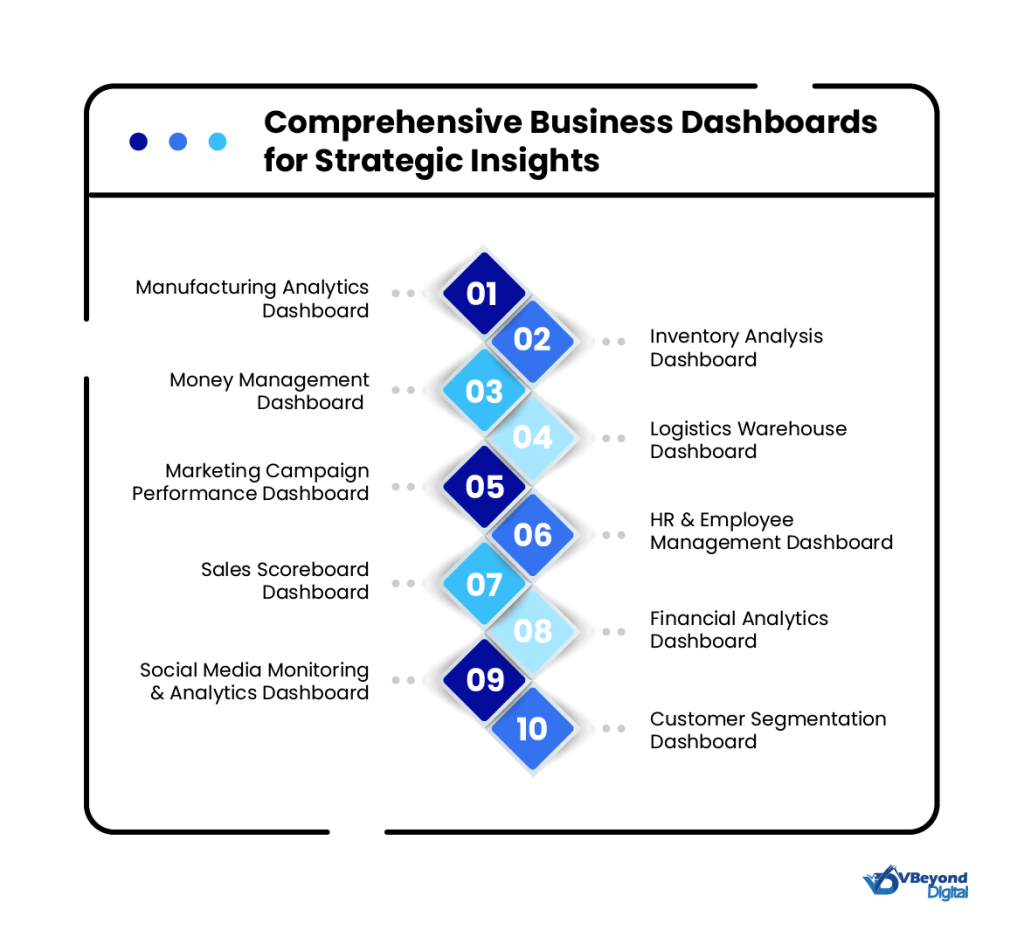

Top 10 Types of Power BI Dashboards for Heavy Manufacturing

Manufacturing Analytics Dashboard

Purpose: Central to monitoring and evaluating production processes, this dashboard facilitates the visualization of production numbers, resource usage, machine failures, and quality check metrics.

Benefits: Enhances decision-making by providing real-time production monitoring that can pinpoint potential equipment failures and areas needing proactive maintenance, thus increasing Overall Equipment Effectiveness (OEE).

Inventory Analysis Dashboard

Purpose: Essential for managing stock levels efficiently, this dashboard offers insights into stock performances, forecasting stock availability, and planning replenishment based on current data trends.

Benefits: Helps maintain optimal inventory levels to ensure peak performance and avoid overstock or stockouts, which is crucial for managing costs and meeting production demands.

Money Management Dashboard

Purpose: Tracks and analyzes financial data such as income, expenses, profitability, and cash flows from various sources including market data and accounting systems.

Benefits: Assists in improving financial forecasting, budgeting, and strategic planning, helping businesses minimize financial risks and optimize cash flow management.

Logistics Warehouse Dashboard

Purpose: Provides comprehensive visibility into warehouse operations, displaying critical data on worker utilization, shipments, and inventory levels.

Benefits: By incorporating machine learning algorithms, this dashboard aids in proactive planning and forecasting, which can significantly reduce the risk of inventory excess or shortages.

Marketing Campaign Performance Dashboard

Purpose: Offers a detailed overview of the effectiveness of marketing campaigns by showing data on metrics like cost per acquisition (CPA), return on investment (ROI), impressions, and conversions.

Benefits: Enables the analysis of campaign reach and effectiveness across various channels, enhancing brand awareness and customer engagement strategies.

HR and Employee Management Dashboard

Purpose: Centralizes access to vital employee metrics and data, crucial for effective human resource management.

Benefits: Provides insights into employee demographics, performance, and turnover, aiding HR teams in strategic decision-making, policy implementations, and employee experiences. Helps in workforce planning and optimization by visualizing trends and patterns in employee data.

Sales Scoreboard Dashboard

Purpose: Integrates data from various systems, including CRM and financial tools, to improve tracking and analysis of sales performance.

Benefits: Facilitates real-time tracking of sales metrics, enhancing goal setting and performance evaluation. Supports strategic sales planning and forecasting by providing a unified view of sales data across the organization.

Financial Analytics Dashboard

Purpose: Analyzes financial performance across various parameters including profitability, liquidity, and solvency.

Benefits: Empowers finance professionals to make informed decisions that drive business growth and stability. Supports advanced financial analyses like trend and variance analysis, aiding in strategic financial planning and risk mitigation.

Social Media Monitoring & Analytics Dashboard

Purpose This dashboard provides comprehensive insights into key social media metrics such as reach, engagement, and sentiment, which are indispensable for shaping effective digital marketing strategies in the manufacturing sector.

Benefits

Enhances Brand Awareness: By monitoring social interactions and engagements, manufacturers can fine-tune their branding efforts to better resonate with their target audience.

Drives Product Innovation: Leveraging customer feedback and social sentiments, manufacturers can identify pain points and opportunities for product improvement or development, ensuring their offerings meet the evolving expectations of consumers.

Optimizes Customer Engagement: With insights into the effectiveness of social media campaigns across various platforms, marketing professionals can tailor their strategies to enhance customer interaction and satisfaction.

Customer Segmentation Dashboard

Purpose: Enables the analysis of customer data to segment customers based on demographics, purchase history, and behaviors.

Benefits: Supports targeted marketing strategies and personalized customer interactions by providing insights into customer preferences and purchasing patterns. Helps optimize marketing campaigns and improve customer relationship management by identifying key customer segments.

Integrating Power BI Dashboards into Business Strategy

Implementation Steps:

Customization:

Tailoring Dashboards: Customize Power BI dashboards to meet specific needs of the manufacturing sector by focusing on key operational metrics such as production efficiency, machine uptime, and quality control.

Adaptive Visualization: Develop dashboards that adapt to the dynamic needs of heavy manufacturing, enabling quick access to crucial data points that facilitate immediate and informed decision-making.

Integration:

Seamless Connectivity: Integrate Power BI seamlessly with existing IT infrastructure, which includes connecting with ERP systems, IoT devices, and other data sources to ensure a smooth flow of data from shop floors to executive levels.

Unified Data Platform: Employ Power BI to unify disparate data sources across the manufacturing process, providing a holistic view that enhances strategic decision-making and operational agility.

Strategic Deployment:

Role-based Access: Implement role-based dashboard access to ensure that various levels of management receive the data visualization pertinent to their operational focus.

Real-Time Operational Insight: Utilize Power BI’s real-time data processing capabilities to monitor manufacturing operations continuously, enabling immediate identification and rectification of production anomalies.

Advanced Features Utilization:

Predictive Analytics: Leverage Power BI’s advanced analytics forecast production trends and potential downtimes, thereby planning maintenance and resources more efficiently.

Mobile Accessibility: Ensure that Power BI dashboards are mobile-friendly, allowing decision-makers and floor managers to access critical data on-the-go, enhancing responsiveness and decision-making speed.

Success Stories in Heavy Manufacturing

Case Study 1: Körber’s Strategic Transformation in Pharmaceutical Production

Problem: Pharmaceutical manufacturing is experiencing rising global demand, which calls for scalable and flexible production systems. Companies face challenges such as high capital and resource expenditures, stringent regulatory compliance, and maintaining robust supply chain agility. The complexity of managing every stage of a product’s lifecycle—from R&D through to final packaging—requires advanced technological solutions to ensure quality and eliminate human error.

Solution: To address these challenges, Körber transformed its market-leading PAS-X Manufacturing Execution System (MES) into a cloud-based Software as a Service (SaaS) solution. This strategic enhancement utilizes the robust stability of Microsoft Azure and Microsoft Cloud for Manufacturing, including Azure Kubernetes Service (AKS). This transition enables scalable deployments and ongoing maintenance of MES systems, ensuring flexibility and reducing both initial capital investment and operational costs.

Benefit: Körber’s customers have benefited significantly from this transformation, experiencing a 75 percent reduction in IT responsibility and a 65 percent decrease in initial investment. The scalability of the solution allows for easy updates and enhancements, fostering continuous innovation within their operations. Moreover, customers report a 50 percent reduction in time to market, greatly enhancing their competitive edge. Enhanced security features provided by Microsoft Defender for Cloud assure the safety of strategic applications, while AI integrations promise more efficient and adaptive manufacturing plants in the future.

Case Study 2: Sandvik Coromant’s Data Reporting Transformation with Power BI

Problem: Sandvik Coromant, a leading tooling solutions provider, needed to upgrade its decade-old architecture to handle increasing data volumes and complexity. The company faced challenges in harmonizing data from multiple sources, maintaining expensive hardware, and delivering timely insights, which slowed down decision-making and impacted operational efficiency.

Solution: Sandvik Coromant transitioned to Microsoft Azure and Power BI to modernize its data architecture. By moving from on-premises servers to Azure Virtual Machines and utilizing a suite of Azure services like Cosmos DB, Data Factory, and Databricks, the company created a reactive data platform. Power BI was then used to consolidate and analyze data, providing a comprehensive view of business operations and enabling self-service business intelligence across the organization.

Benefit: The new solution reduced hardware costs and improved the ability to manage and scale data operations. Power BI enabled Sandvik Coromant to replace manual Excel processes with automated dashboards, providing real-time insights into sales and other critical areas. The introduction of a Power BI Center of Excellence further streamlined reporting and analytics, enhancing data-driven decision-making and operational efficiency.

To know more, read the full Microsoft Customer Success Story here: Sandvik Coromant’s Digital Transformation.

Conclusion

The integration of Power BI within the heavy machinery manufacturing sector marks a significant shift towards more agile, informed, and efficient operations. By harnessing the capabilities of manufacturing data integration, real-time production monitoring, and predictive maintenance, businesses can not only foresee and mitigate potential disruptions but also enhance productivity and operational fluency.

Real-Time Data and Decision-Making: Utilizing Power BI, industry leaders are equipped with the tools necessary for making data-driven decisions that resonate across production lines and supply chains. This level of analysis supports not only day-to-day management but also strategic long-term planning.

Economic and Operational Advantages: The direct benefits of implementing Power BI dashboards include reduced downtime, enhanced labor productivity analysis, and more efficient use of resources, all of which contribute to a healthier bottom line. Moreover, the ability to monitor and adjust to manufacturing conditions in real time translates into significant cost savings and enhanced product quality.

Looking Forward: As we advance, the role of Power BI is set to expand, further embedding itself as a pivotal element of manufacturing analytics. Its ability to process and visualize vast amounts of data will continue to be crucial in driving the evolution of the manufacturing sector towards more sustainable and profitable practices.

By adopting Power BI, manufacturers are not just keeping up with technological advancements; they are staying ahead, ensuring continued relevance in a rapidly changing industrial landscape. This strategic adoption of advanced analytics is not just about improving processes—it is about reshaping the future of manufacturing.