Automating DTC Fulfillment with Drop Shipment on Dynamics 365 Business Central

Section

Table of Contents

- What’s Holding Back DTC Fulfillment and Why It Needs to Change?

- Fulfillment Models Explained: Drop Shipping vs. Special Orders

- How to Set Up and Execute Drop Shipments and Special orders in Business Central

- Common Issues (and How to Fix Them)

- Best Practices to Stay Ahead of Fulfillment Errors

- Conclusion

- FAQs ( Frequently Asked Questions)

- Manual order entry, siloed sales-to-purchase workflows, and warehouse bottlenecks are still holding back fulfillment for many DTC brands. But with drop shipping in Dynamics 365 Business Central and built-in special-order automation, you can scale without scaling complexity.

- This blog takes you through how to eliminate manual steps, route orders directly from vendors or through your warehouse based on product logic and reduce cycle time without custom development or operational bloat.

- From setting up purchasing codes to executing batch POs using the business central requisition worksheet, you’ll learn how to turn Business Central into a lean, reliable, and fully automated order fulfillment system.

- We’ll also cover common setup pitfalls, real-world tips for managing SKU variety, and the workflows that help your ops team move faster without losing control.

- Read further to build a fulfillment engine that runs itself.

For DTC brands, fulfillment is no longer a backend function but part of the brand experience. Every late delivery or missing item impacts loyalty, reviews, and lifetime value. As order volume grows across channels, the need for smarter systems becomes non-negotiable.

That’s where drop shipping in Dynamics 365 Business Central gives growing DTC businesses a crucial edge.

By linking sales and purchase orders automatically, Business Central allows brands to route orders through vendors or warehouses based on item needs without adding manual steps. The result is a faster, cleaner, and more reliable path for the customer.

This form of automated order fulfillment minimizes operational overhead and supports lean scaling. Whether you’re moving thousands of SKUs across Shopify, Amazon, and retail POS, or expanding to new regions.

It also integrates critical tools like the business central requisition worksheet to help batch-create vendor orders, align purchasing behavior, and reduce delays.

This blog shows you how to:

- Set up Business Central for smart fulfillment

- Configure drop shipments and special orders for each SKU

- Automate drop shipping in Microsoft Dynamics 365 without writing custom code

- Build long-term fulfillment flexibility into your DTC operations

Read on to learn how fulfillment can scale with your growth, not slow it down.

What’s Holding Back DTC Fulfillment and Why It Needs to Change?

DTC brands today face a fulfillment paradox. On the one hand, customers expect next-day delivery, real-time order visibility, and personalized experiences. On the other hand, most operations teams are stuck reconciling spreadsheets, chasing vendor emails, or trying to make disconnected systems work together. As order volumes grow, fulfillment becomes harder to manage, not easier.

If your current setup still requires manual steps to link sales and purchase orders, or if you’re routing every order through your own warehouse by default, you’re likely to see the cracks. Slow fulfillment leads to poor reviews. Stockouts lead to churn. And warehouse dependency restricts how fast you can scale.

Here’s what typically holds DTC fulfillment back and how drop shipping in Dynamics 365 Business Central helps fix it.

1. Manual Sales-to-Purchase Order Matching Slows Everything Down

It starts simply: a customer places an order. But in many setups, someone has to manually create a purchase order, match quantities, add vendor details, and confirm logistics every single time.

With automated order fulfillment, Business Central links sales and purchase orders automatically. You can generate vendor POs with the right shipping info, mark items as drop shipped, and reduce rework without touching multiple screens. That frees your ops team to focus on customer service, exception handling, or scaling campaigns, not copy-pasting data.

2. Inventory Chaos: Too Much Here, Not Enough There

Overstocking ties up cash. Understocking damages your reputation. For DTC brands dealing with hundreds of SKUs and constant demand variability, static reorder points don’t cut it.

Business Central helps solve this by giving you the ability to assign fulfillment logic per item. You might route standard SKUs through drop shipping in Dynamics 365 Business Central, while routing temperature-sensitive, bundled, or high-value items through special orders.

This hybrid fulfillment model forms the basis for effective Business Central Drop Shipment Resolutions where orders are automatically routed based on business logic, not guesswork.

3. Multi-Channel Complexity Creates Workflow Clutter

You’re likely selling on multiple platforms like your own site, Amazon, retail partners, and more. Each has different expectations for speed, documentation, and fulfillment logic. If your internal systems aren’t synchronized, mistakes multiply.

The business central requisition worksheet solves this by letting your team pull in open sales orders from all channels and generate the corresponding vendor POs in batches. This keeps everything unified even as channels, SKUs, and suppliers grow.

4. Lack of Automation Blocks Scale

Manual workarounds may be held for your first thousand orders. But after that, they started collapsing. You hire more people, add more checks, and still can’t catch up. This isn’t a people problem, it’s a system problem.

When you automate drop shipping in Microsoft Dynamics 365, you eliminate unnecessary effort. Fulfillment flows adapt in real time. SKUs can be fulfilled based on availability, vendor terms, or margin strategy with little to no manual intervention.

And because Business Central is already integrated with your finance, inventory, and reporting systems, you maintain full traceability and audit readiness without slowing down.

If you’re struggling to meet fulfillment SLAs or constantly reacting to missed shipments, the problem is its architecture. The next section breaks down how Business Central helps you implement the right flow for every order, without compromising speed or control.

Streamline Your DTC Fulfillment

Fulfillment Models Explained: Drop Shipping vs. Special Orders

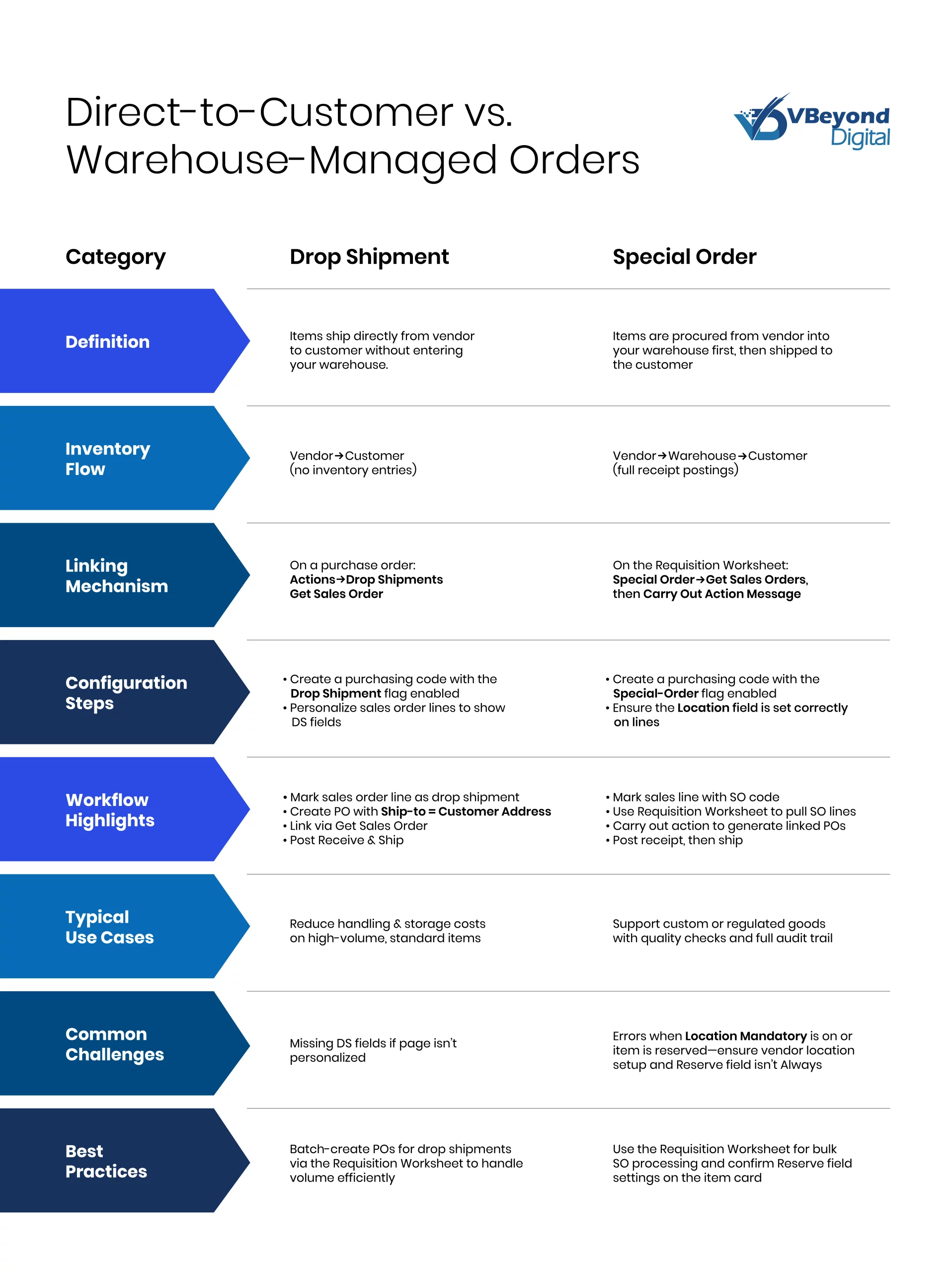

DTC brands need more than just speed, they need control. One product might benefit from a warehouse-managed shipment. Another might be better routed directly from your vendor to the customer. Dynamics 365 Business Central gives you the flexibility to do both.

But choosing the right fulfillment path starts with understanding two native capabilities: drop shipping and special orders.

Drop Shipping in Dynamics 365 Business Central: Built for Speed

In a drop shipment model, customer orders are fulfilled directly by your vendor. The product never enters your warehouse. This reduces touchpoints, accelerates delivery, and eliminates redundant handling.

Here’s how it works:

- A customer places an order through your storefront or POS.

- The system links the sales order to a purchase order automatically.

- The vendor ships directly to the customer, and your team never touches the product.

- Both documents are posted together for clean financial reconciliation.

This type of automated order fulfillment is ideal for fast-moving, high-volume SKUs especially when you’re scaling rapidly and want to avoid inventory risk. It also integrates seamlessly with your ecommerce workflows and vendor SLAs.

Special Orders: Control and Compliance, When Needed

Not every order can be skipped at the warehouse. Some products require quality checks, custom packaging, or compliance tracking. For these, Business Central supports special order fulfillment, a flow where goods are first received into your facility and then shipped out to the customer.

This approach adds an extra step but gives you:

- Full visibility over inbound stock.

- The ability to apply batch or serial tracking.

- Flexibility for bundling, kitting, or product personalization.

For example, a personalized skincare set, or a high-value electronics bundle might use special order routing, while a standard t-shirt gets dropped shipped from the vendor.

Choosing the Right Flow for Each SKU

With Business Central, you don’t have to hardcode one fulfillment model across your catalog. Instead, you can configure fulfillment rules per item or vendor and control how the system behaves by assigning purchasing codes and logic triggers.

When implemented correctly, these fulfillment models are part of your Business Central Drop Shipment Resolutions strategy allowing you to minimize handling without sacrificing traceability.

And with support for batch PO generation via the business central requisition worksheet, even high-volume DTC brands can manage complex order flows without the operational burden.

How to Set Up and Execute Drop Shipments and Special orders in Business Central

Once you’ve decided which products follow a drop shipment model and which require special order handling, the next step is configuring the system to make these flows automatic. The good news? You don’t need developers or custom integrations.

Dynamics 365 Business Central makes it easy to set up fulfillment rules using built-in configuration elements for purchasing codes, item defaults, and personalization. Once in place, your team can execute clean, linked order flows across hundreds of SKUs with minimal effort.

Here’s how to get it done.

Step 1: Define Purchasing Codes

Purchasing codes are the logic engines that tell Business Central whether a product should be dropped, shipped, specially ordered, or handled through your warehouse.

To create them:

- Go to Purchasing Codes for setup.

- Add short, readable codes (e.g., DS for Drop Shipment, SO for Special Order).

- Enable the relevant checkbox for each type.

- This small step is what powers larger workflows by triggering the correct fulfillment path for each line item automatically.

Step 2: Assign Defaults on Item Cards

To avoid manual selection every time a sales order is entered, set default purchasing codes at the item level.

In each item card:

- Assign the relevant purchasing code (DS or SO).

- Set reserve rules as needed (drop shipments should generally not allow reservation).

- This ensures the system knows what to do as soon as the item is added to a sales order; no human intervention is required.

Step 3: Personalize Sales Order Screens

By default, not all fulfillment fields are visible on the sales order page. You’ll want your users to clearly see and control the purchase process.

Use the Personalization Mode to add:

- Purchasing Code

- Drop Shipment (toggle)

- Special Order (toggle)

- Now your team can check or adjust fulfillment instructions at a glance, reducing errors and boosting order clarity.

Step 4: Execute Drop Shipment Workflow

Once an item is marked for drop shipment:

- Create the sales order as usual.

- Generate a linked purchase order by selecting Get Sales Order under Drop Shipments.

- Set the ship-to address as the customer’s.

- When fulfilled, post the receipt on the PO and shipment on the SO in one action.

If you’re processing high volume, use the business central requisition worksheet to pull open sales orders marked for drop shipping and create all linked POs in one batch. That’s how you scale automated order fulfillment without touching each order manually.

Step 5: Execute Special Order Workflow

For special orders:

- Sales lines are marked with the SO

- Open the business central requisition worksheet and select Special Order as the source type.

- Use Get Sales Orders to pull relevant items.

- Click Carry Out Action Message to generate linked POs.

- When goods arrive, receive them into inventory first, then ship and invoice the SO.

This ensures traceability, warehouse control, and item-level customization while still streamlining the backend process.

Whether you’re fulfilling 10 orders a day or 10,000, the ability to automate drop shipping in Microsoft Dynamics 365 gives your team the tools to move fast without losing visibility.

Even the best-configured system can break down without guardrails. For DTC brands using drop shipping in Dynamics 365 Business Central, small missteps like missing files or misaligned item settings can lead to fulfillment delays, order mismatches, and frustrated customers.

Here are the most common challenges teams face, along with best practices to prevent them, so your automated order fulfillment process remains clean, scalable, and stress-free.

Common Issues (and How to Fix Them)

1. Missing Drop Shipment or Special-Order Fields on Sales Orders

Fix: Use page personalization to add Purchasing Code, Drop Shipment, and Special-Order fields. Set it up per role to ensure all users see what they need.

2. Location Mandatory Errors During Drop Shipping

Fix: If your system prompts for a location on drop shipped lines, ensure the vendor card includes a default location, or disable “Location Mandatory” for drop shipment vendors.

3. Reserved Items Blocking Drop Shipment Posting

Fix: Drop shipments don’t allow reservations. On the item card, set the Reserve field to “Optional” or “Never” to avoid conflicts during posting.

4. Requisition Worksheet Not Pulling Sales Orders

Fix: Double-check that items have the correct purchasing code (DS or SO) and that the correct fulfillment method is enabled. The business central requisition worksheet pulls only correctly flagged lines.

Best Practices to Stay Ahead of Fulfillment Errors

1. Use Simple, Standardized Purchasing Codes

Short codes like DS and SO are easier to train, standardize, and troubleshoot across teams.

2. Batch Your Purchase Orders

Use the business central requisition worksheet for both drop shipment and special orders. It ensures accuracy at scale and reduces the risk of missing linked documents.

3. Align Reserve Rules with Fulfillment Type

Items intended for drop shipping should not have reservation conflicts. Set reserve behavior directly on the item card.

4. Review Your Logic Quarterly

As your product catalog evolves, so should your purchasing rules. Periodically revisit your Business Central Drop Shipment Resolutions to ensure your fulfillment logic still aligns with business needs.

These aren’t advanced configurations, they’re everyday sanity checks. But they make all the difference when you’re processing thousands of DTC orders a week and can’t afford delays.

Conclusion: Delivering Faster, Smarter Fulfillment with Business Central

For modern DTC brands, fulfillment is no longer an afterthought, it’s a competitive differentiator. Whether you’re aiming for faster delivery, leaner inventory, or multi-channel growth, the ability to control and scale order flows matters just as much as the product you ship.

Implementing drop shipping in Dynamics 365 Business Central gives you that control. It empowers your team to automate everyday fulfillment actions, minimize warehouse dependency, and route orders based on what’s best for the customer, not just what your system can support.

With the right setup:

- Automated order fulfillment becomes part of your daily rhythm, not a wishlist item.

- You can define logic once and execute it across hundreds of SKUs, suppliers, and regions.

- Tools like the business central requisition worksheet keep batch operations fast and error-free.

- You stay audit-ready and compliant, even as order volume spikes.

And when you automate drop shipping in Microsoft Dynamics 365, you’re not just removing friction, you’re unlocking a foundation that scales with your business, not against it.

Ready to automate and grow your DTC operations? Start your Business Central rollout with us.

FAQs (Frequently Asked Question)

Drop shipment in Business Central is a process where goods are shipped directly from your vendor to the customer, bypassing your warehouse. It removes the need for inventory handling and speeds up order fulfillment.

You can automate drop shipping in Microsoft Dynamics 365 by using purchasing codes, default item settings, and the requisition worksheet to auto-link sales and purchase orders. This reduces manual steps and ensures accurate processing.

Use special orders when you need to receive goods into your warehouse first such as for quality checks, labeling, or regulatory compliance before shipping to the customer.

Yes, Business Central supports both drop shipment and special-order workflows in parallel. You can assign fulfillment paths per item or order using purchasing codes and automation rules.

Drop shipments skip inventory and ship directly to the customer. Special-order routes the product through your warehouse before final delivery. Both are supported by automation in Business Central.