The Path to Intelligent Automotive Supply Chain Management with IoT and Dynamics 365

Section

Table of Contents

- Addressing Complexities in Automotive Supply Chain Management

- Integrating IoT and Dynamics 365 for Solutions

- Achieving Real-Time Supply Chain Visibility

- Improving Operational Efficiency in Manufacturing

- Ensuring Quality Control and Regulatory Compliance

- Addressing Challenges in Implementation

- Conclusion

- FAQs ( Frequently Asked Questions)

The automotive industry is no stranger to innovation. From the first assembly lines to today’s smart factories, technology continues to reshape how vehicles are produced and delivered. However, as supply chains grow more intricate and globalized, managing them has become more complex than ever. Traditional methods of tracking, monitoring, and maintaining supply chain operations are no longer sufficient. Delays, inefficiencies, and unexpected breakdowns can disrupt production, leading to significant financial losses and dissatisfied customers.

Enter the Internet of Things (IoT) and Dynamics 365. Together, these technologies offer a powerful solution for modern automotive supply chain management. IoT enables continuous data collection from various points across the supply chain, while Dynamics 365 consolidates this data, providing actionable insights and real-time visibility. The combination of these tools allows manufacturers to optimize their processes, predict potential disruptions, and enhance collaboration with suppliers.

This intelligent approach transforms supply chains from reactive systems into proactive, self-optimizing networks. Predictive maintenance, real-time inventory tracking, and seamless coordination between suppliers and manufacturers are no longer futuristic ideals—they’re achievable realities.

In this blog, we’ll explore how IoT and Dynamics 365 can address the complexities of automotive supply chain management, improve operational efficiency, and drive smarter decision-making. From real-tme data collection to predictive analytics, we’ll break down each component that contributes to a streamlined, resilient, and future-ready supply chain

Let’s start by examining the challenges automotive manufacturers face today and how these technologies provide game-changing solutions.

Addressing Complexities in Automotive Supply Chain Management

The automotive supply chain is a complex, global network involving numerous suppliers, manufacturers, and distributors. This intricate system faces several challenges that can disrupt operations and affect overall efficiency.

Globalization and Geopolitical Risks

The globalization of the automotive supply chain management has led to increased interdependence among suppliers and manufacturers worldwide. This interconnectedness means that regional disruptions, such as natural disasters or geopolitical tensions, can have far-reaching impacts. For instance, the 2020–2023 global chip shortage significantly affected automotive production, highlighting the vulnerability of relying on a limited number of suppliers for critical components.

Supply Chain Disruptions

Recent events have exposed the fragility of the automotive supply chain management. The COVID-19 pandemic, for example, caused widespread disruptions due to factory shutdowns and transportation delays. Additionally, geopolitical tensions have led to trade restrictions, further complicating the flow of goods. These disruptions have underscored the need for greater resilience and adaptability within the supply chain.

Just-In-Time Manufacturing Challenges

The automotive industry has traditionally relied on just-in-time (JIT) manufacturing to minimize inventory costs. While efficient, this approach leaves little room for error. Any delay in the supply chain can halt production, leading to significant financial losses. The chip shortage, for example, forced manufacturers to halt production due to a lack of essential components, revealing the limitations of JIT in the face of unexpected disruptions.

Regulatory Compliance and Quality Control

Automotive manufacturers must adhere to stringent regulatory standards and ensure high-quality products. Managing compliance across a vast network of suppliers is challenging, especially when dealing with varying regulations across different regions. Ensuring that all parts meet safety and environmental standards requires meticulous oversight and coordination.

Technological Advancements and Integration

The rapid pace of technological innovation presents both opportunities and challenges. Integrating new technologies into existing systems can be complex and costly. Moreover, as vehicles become more technologically advanced, the supply chain must adapt to source and deliver new types of components, such as those required for electric vehicles (EVs). This transition necessitates significant changes in procurement and manufacturing processes.

Labor Shortages and Skills Gaps

The automotive industry is experiencing labor shortages and a skills gap, particularly in areas requiring advanced technical expertise. Attracting and retaining skilled workers is essential for maintaining production levels and ensuring quality. Investing in workforce development and training programs is crucial to address this challenge.

Drive Smarter Supply Chain Decisions

Integrating IoT and Dynamics 365 for Solutions

Automotive supply chain management is a complex network that demands real-time visibility, predictive maintenance, and seamless collaboration to maintain operational efficiency. Integrating the Internet of Things (IoT) with Microsoft Dynamics 365 offers a comprehensive solution to these challenges, enabling manufacturers to transform their supply chain operations.

Implementing Sensor Data Intelligence

Microsoft’s Sensor Data Intelligence, formerly known as IoT Intelligence, allows organizations to drive business processes based on IoT signals from production floor equipment. By deploying sensors on machinery, manufacturers can collect real-time data on performance metrics, environmental conditions, and operational statuses. This data is transmitted to Dynamics 365 Supply Chain Management, where it is analyzed to provide actionable insights.

Enhancing Predictive Maintenance

The integration of IoT with Dynamics 365 enables predictive maintenance strategies by monitoring equipment health in real-time. Sensors detect anomalies and usage patterns, allowing the system to forecast potential failures and schedule maintenance proactively. This approach reduces unexpected downtime and extends the lifespan of assets, leading to significant cost savings.

Streamlining Operations through Automation

Automating routine tasks is essential for improving operational efficiency in manufacturing. IoT devices can monitor inventory levels and production processes, triggering automated responses within Dynamics 365. For example, when inventory reaches a predefined threshold, the system can automatically generate purchase orders, ensuring that production is not halted due to material shortages.

Facilitating Supplier Collaboration

Effective supplier collaboration is crucial in addressing automotive supply chain management challenges. Integrating IoT data with Dynamics 365 enhances transparency and communication between manufacturers and suppliers. Real-time data sharing enables suppliers to align their production schedules with manufacturers’ needs, reducing lead times and improving the overall efficiency of the supply chain. Furthermore, this integration facilitates collaborative planning and forecasting, allowing all parties to respond swiftly to market changes and demand fluctuations. By leveraging supplier collaboration tools within Dynamics 365, organizations can build stronger, more responsive partnerships.

Ensuring Regulatory Compliance

The automotive industry is subject to stringent regulatory standards. Integrating IoT with Dynamics 365 aids in maintaining compliance by providing detailed records of processes and product histories. IoT sensors can monitor parameters critical to regulatory compliance, such as temperature and humidity levels during production. Dynamics 365 stores this data, generating compliance reports and facilitating audits. This systematic approach ensures that all aspects of production adhere to industry standards, reducing the risk of non-compliance penalties and enhancing product quality.

Achieving Real-Time Supply Chain Visibility

In the automotive industry, real-time visibility into the supply chain is crucial for maintaining operational efficiency and responding swiftly to disruptions. Deploying Internet of Things (IoT) technology and devices while integrating them with Microsoft Dynamics 365 enables continuous data collection and centralized monitoring, providing a comprehensive view of the supply chain.

Collecting Data Continuously with IoT Sensors

IoT sensors are deployed across various points in the automotive supply chain management to monitor equipment performance, track inventory levels, and assess environmental conditions. These sensors collect data in real-time, offering immediate insights into the status of manufacturing processes and the movement of goods.

For example, sensors can monitor the temperature and humidity levels in storage facilities to ensure that components are stored under optimal conditions, preventing quality degradation. Additionally, IoT devices can track the location and condition of shipments, providing real-time updates on delivery status and enabling proactive management of potential delays.

This continuous data collection allows manufacturers to detect anomalies promptly, such as equipment malfunctions or inventory shortages, facilitating swift corrective actions to minimize disruptions.

Centralizing Monitoring through Dynamics 365 Integration

Integrating IoT data with Dynamics 365 centralizes information, providing a unified platform for monitoring and analysis. Dynamics 365 consolidates data from various IoT devices, offering a comprehensive overview of the supply chain.

This integration enables the application of advanced analytics and machine learning algorithms to identify patterns, predict potential disruptions, and optimize processes. For instance, by analyzing data from production lines, manufacturers can forecast demand for specific components and adjust procurement strategies accordingly, ensuring that inventory levels align with production needs

Moreover, centralized monitoring enhances collaboration among different departments and stakeholders, as all parties have access to the same real-time data, facilitating coordinated decision-making and efficient problem-solving.

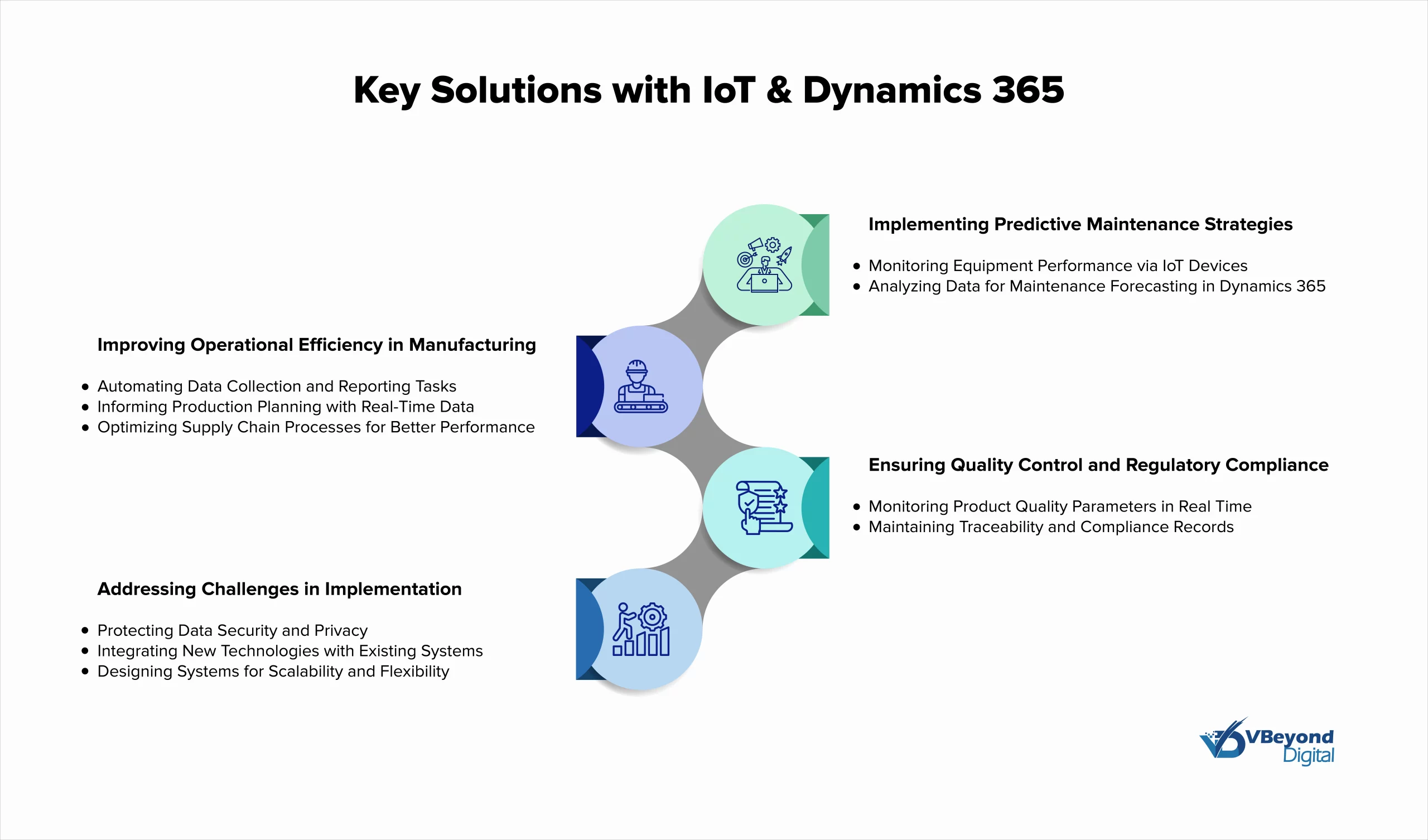

Implementing Predictive Maintenance Strategies

In the automotive industry, unplanned equipment failures can lead to significant production delays and increased operational costs. To address these automotive supply chain challenges, implementing predictive maintenance strategies has become essential. By leveraging Internet of Things (IoT) devices and integrating data into platforms like Microsoft Dynamics 365, manufacturers can transition from reactive to proactive maintenance approaches, enhancing operational efficiency in manufacturing.

Monitoring Equipment Performance via IoT Devices

IoT devices play a pivotal role in predictive maintenance by continuously monitoring equipment performance. Sensors collect real-time data on various parameters such as temperature, vibration, and pressure. This data is crucial for identifying early signs of wear and tear or potential failures.

For instance, in automotive manufacturing, sensors installed on assembly line machinery can detect anomalies that may indicate impending malfunctions. By capturing this information promptly, maintenance teams can address issues before they escalate, thereby minimizing downtime and maintaining the flow of the automotive supply chain management.

Analyzing Data for Maintenance Forecasting in Dynamics 365

Integrating IoT data with Dynamics 365 enables comprehensive analysis and forecasting. The platform utilizes machine learning algorithms to process sensor data, identifying patterns and predicting when maintenance should be performed.

This predictive analytics capability allows maintenance schedules to be optimized, ensuring interventions occur just in time to prevent failures without unnecessary servicing. Such precision in maintenance planning not only extends the lifespan of equipment but also contributes to overall operational efficiency in manufacturing.

Benefits: Reducing Downtime and Maintenance Costs

Implementing predictive maintenance in the automotive industry offers several benefits:

- Reduced Downtime: By anticipating and addressing issues before they lead to equipment failure, manufacturers can significantly decrease unplanned downtime, ensuring that production schedules remain on track.

- Lower Maintenance Costs: Targeted maintenance activities prevent extensive damage, reducing the need for costly repairs and replacements.

- Enhanced Safety: Proactively maintaining equipment minimizes the risk of accidents caused by machinery failures, promoting a safer working environment.

These advantages collectively enhance the resilience and efficiency of the automotive supply chain management, addressing common auto industry supply chain issues.

Case Study: Enhancing Maintenance in Automotive Plants

Consider an automotive manufacturing plant that integrated IoT sensors with Dynamics 365 to monitor its production equipment. The sensors provided real-time data on machine health, which was analyzed to predict potential failures.

As a result, the plant could schedule maintenance during planned downtimes, avoiding unexpected halts in production. This approach led to a 20% reduction in maintenance costs and a 15% increase in equipment availability, exemplifying the effectiveness of predictive maintenance in the automotive industry.

By adopting predictive maintenance strategies, automotive manufacturers can proactively address equipment issues, thereby enhancing operational efficiency and ensuring a more robust and responsive supply chain.

Improving Operational Efficiency in Manufacturing

In the automotive industry, operational efficiency is paramount to maintaining competitiveness and meeting market demands. Integrating Internet of Things (IoT) technologies with Microsoft Dynamics 365 offers manufacturers innovative solutions to streamline processes, reduce costs, and enhance productivity.

Automating Data Collection and Reporting Tasks

Manual data collection in manufacturing is often time-consuming and prone to errors, leading to inefficiencies and delays. IoT devices address this challenge by automating the gathering of critical operational data. Sensors installed on machinery and equipment can monitor parameters such as temperature, pressure, and operational status in real-time.

This data is transmitted directly into Dynamics 365, where it is processed and analyzed. Automating these tasks not only accelerates data collection but also ensures higher accuracy, enabling manufacturers to make informed decisions swiftly. For example, real-time monitoring can alert operators to deviations from standard operating conditions, allowing for immediate corrective actions and minimizing potential disruptions.

Informing Production Planning with Real-Time Data

Effective production planning requires access to up-to-date information. By integrating IoT data into Dynamics 365, manufacturers gain real-time insights into various aspects of the production process, including machine performance, inventory levels, and workforce availability.

This integration facilitates dynamic scheduling, where production plans can be adjusted in response to real-time data. For instance, if IoT sensors detect a slowdown in a particular machine, production managers can reallocate resources or reschedule tasks to maintain overall efficiency. Such responsiveness reduces bottlenecks and ensures that production targets are met consistently.

Optimizing Supply Chain Processes for Better Performance

he automotive supply chain management is intricate, involving multiple suppliers and complex logistics. IoT integration provides end-to-end visibility across the supply chain, enabling manufacturers to track materials and components from suppliers to the production floor.

Dynamics 365 consolidates this information, offering a comprehensive view of the supply chain’s status. Advanced analytics can identify inefficiencies, such as delays in material delivery or underutilized resources. By addressing these issues proactively, manufacturers can optimize workflows, reduce lead times, and improve overall supply chain performance.

Moreover, enhanced visibility supports better collaboration with suppliers, as real-time data sharing fosters transparency and trust. This collaborative approach enables joint problem-solving and continuous improvement initiatives, further enhancing operational efficiency.

Ensuring Quality Control and Regulatory Compliance

In the automotive industry, maintaining stringent quality control and adhering to regulatory compliance are paramount to sustaining customer trust and meeting legal obligations. The integration of Internet of Things (IoT) technologies with Microsoft Dynamics 365 offers a robust framework to address these critical aspects effectively.

Monitoring Product Quality Parameters in Real Time

IoT sensors embedded within manufacturing equipment enable continuous monitoring of product quality parameters such as temperature, pressure, and humidity. This real-time data collection allows for immediate detection of deviations from established quality standards, facilitating prompt corrective actions.

For instance, in the automotive supply chain management, ensuring that components are manufactured within specified tolerances is crucial. IoT-enabled monitoring systems can alert operators to any anomalies, thereby preventing defective parts from progressing through the production line and reaching customers.

Maintaining Traceability and Compliance Records

Regulatory compliance in the automotive sector mandates comprehensive traceability of materials and processes. Dynamics 365 provides a centralized platform to record and manage this information, ensuring that every component’s journey—from supplier to final assembly—is meticulously documented.

This level of traceability is vital for addressing automotive regulatory compliance requirements, as it enables manufacturers to swiftly conduct recalls, audits, and investigations when necessary. By maintaining detailed compliance records, organizations can demonstrate adherence to industry standards and regulatory mandates, thereby avoiding potential legal penalties and safeguarding their reputation.

Addressing Challenges in Implementation

Integrating Internet of Things (IoT) technologies with Microsoft Dynamics 365 offers significant benefits for the automotive supply chain management. However, this integration presents several challenges that organizations must address to ensure a successful implementation.

Protecting Data Security and Privacy

The deployment of IoT devices across the automotive supply chain management introduces substantial data security and privacy concerns. These devices collect and transmit vast amounts of sensitive information, making them potential targets for cyberattacks. Common vulnerabilities include insecure network services, insufficient authentication, and lack of encryption, which can lead to unauthorized access and data breaches.

To mitigate these risks, organizations should implement robust security measures, such as:

- End-to-End Encryption: Ensuring that data is encrypted during transmission and storage to prevent unauthorized access.

- Strong Authentication Mechanisms: Utilizing multi-factor authentication to verify the identities of users and devices accessing the network.

- Regular Security Audits: Conducting periodic assessments to identify and address potential vulnerabilities within the IoT ecosystem.

Additionally, establishing clear data governance policies is crucial to ensure compliance with data protection regulations and to maintain the privacy of sensitive information.

Integrating New Technologies with Existing Systems

Many automotive manufacturers operate with legacy systems that may not be inherently compatible with modern IoT technologies. Integrating these new technologies requires careful planning to avoid disruptions. Challenges include compatibility issues, proprietary protocols, and the need for standardized interfaces.

Strategies to facilitate seamless integration include:

- Assessment and Planning: Evaluating existing systems to determine integration requirements and developing a comprehensive plan that addresses potential challenges.

- Middleware Solutions: Implementing middleware that can bridge the gap between legacy systems and IoT devices, enabling communication and data exchange.

- Incremental Implementation: Adopting a phased approach to integration, allowing for testing and adjustments to minimize operational disruptions.

By addressing these challenges proactively, organizations can leverage IoT technologies to enhance operational efficiency in manufacturing and strengthen automotive supply chain management.

Designing Systems for Scalability and Flexibilit

As the automotive industry evolves, supply chain systems must be adaptable to changing demands and technological advancements. Designing IoT systems with scalability and flexibility in mind is essential to accommodate future growth and integration of new technologies.

Key considerations include:

- Modular Architecture: Developing systems with modular components allows for easy upgrades and integration of new functionalities without overhauling the entire system.

- Cloud-Based Solutions: Utilizing cloud platforms provides scalable resources that can adjust to varying workloads and support extensive data storage and processing needs.

- Standardized Protocols: Adopting industry-standard communication protocols ensures compatibility with a wide range of devices and systems, facilitating future integrations.

By focusing on scalability and flexibility, organizations can build resilient supply chain systems capable of adapting to industry changes and technological innovations.

Conclusion

The integration of Internet of Things (IoT) technologies with Microsoft Dynamics 365 is revolutionizing automotive supply chain management by addressing key challenges and enhancing operational efficiency. This synergy offers comprehensive solutions to complex issues prevalent in the industry.

Maintaining high-quality standards and adhering to automotive regulatory compliance are critical in the industry. The combined capabilities of IoT and Dynamics 365 enable continuous monitoring of quality parameters and comprehensive traceability, ensuring that products meet stringent regulatory requirements.

The future of the automotive supply chain management is poised for further transformation with advancements in AI and IoT. Microsoft’s ongoing innovations, such as the Sensor Data Intelligence feature in Dynamics 365, are set to enhance data analysis and decision-making capabilities. These developments will further strengthen the supply chain’s resilience and adaptability.

FAQs (Frequently Asked Questions)

The main challenges include globalization risks, supply chain disruptions, just-in-time manufacturing delays, regulatory compliance, technological integration, and labor shortages. These factors can cause inefficiencies and delays in production.

IoT devices collect real-time data from various points in the supply chain, such as equipment status and inventory levels. This helps manufacturers detect issues early, predict maintenance needs, and make informed decisions to avoid delays.

Integrating Dynamics 365 with IoT provides real-time data visibility, automation of routine tasks, improved supplier collaboration, and better decision-making capabilities. This helps manufacturers address supply chain inefficiencies and avoid disruptions.

IoT sensors monitor equipment performance and send data to Dynamics 365, which uses machine learning to predict failures. Maintenance can be scheduled proactively, reducing downtime and lowering repair costs.

IoT sensors track key production parameters like temperature and humidity. Dynamics 365 stores this data, creating detailed compliance records and reports that simplify audits and help manufacturers meet industry standards.